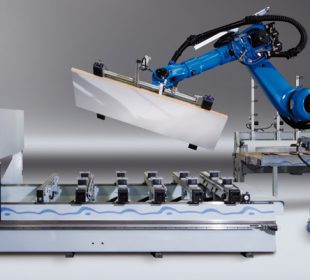

The new Homag CNC machine concept is based on compact technology and almost automatic 360° handling. The Venture 115 can be accessed from all sides, thanks to the new safety Technology, as Homag describes its product.

The Venture 115 five-axis machine is just one of nine possible configurations in this series. There are also three-axis, four-axis, and five-axis entry-level solutions available for horizontal CNC processing. The machine can be commissioned within a day, requires up to 15% less space for installation and offers accurate performance level.

The new BMG 312/V combines both five-axis technology and edge banding in one machine.

The new SWT 200

Accorging to Homag, the new SWT 200 series requires less space, shorter set-up times, and is more user-friendly. This design prioritises efficient use of surfaces in the workshop. The machine is faster and safer to configure, says Homag. Belts can be changed and attached and the grain calibrated in just a few steps. The measurement of workpiece thickness is also automated. There are two additional unit slots for post-processing.

HPP 130 compact saw

The new HPP 130 makes it easier to cut precisely, Homag says. The compact saw is equipped with everything a user needs for cutting single panels. This includes a saw blade projection of 60mm, a cutting length of 3200 mm, and the CADmatic 4 PRACTIVE machine control unit. The HPP 130 costs little more than a well-equipped circular saw while providing a much more precise and efficient cutting process.

Source: Homag

[gravityform id="1" title="true" description="true"]